Silicone is a versatile material with the capacity to withstand a wide range of temperatures. This makes it perfect for creating molds that can be used to produce a variety of end-use products. Silicone is used by product designers, engineers, DIYers, and many other types of manufacturers to make one-off or short runs of parts. This practical guide to silicone mold making will teach you everything you need to know to get started.

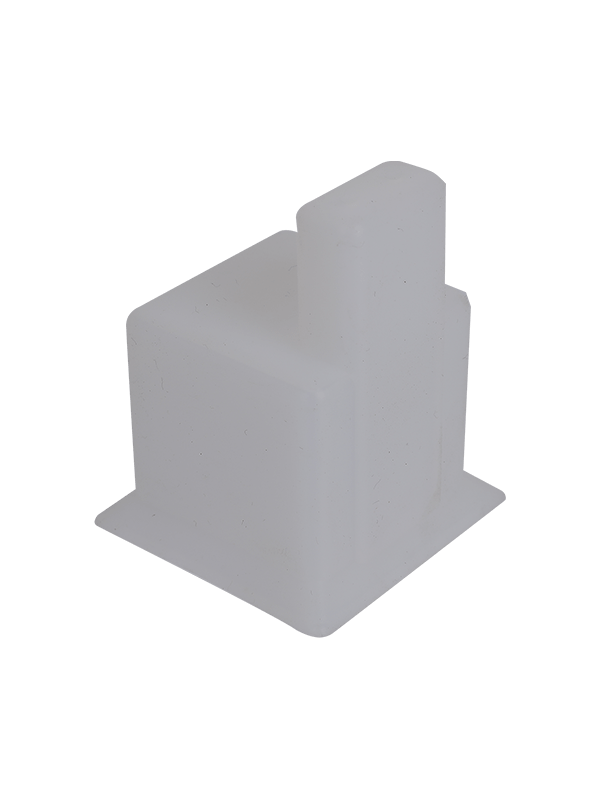

The first step in

silicone molding is constructing the mold housing. Coated MDF is a popular choice for this purpose, but a premade plastic container could also work as long as it has a nonporous surface and a flat bottom. Once the mold box is constructed, it is time to start adding the silicone rubber. To avoid any mistakes, it is highly recommended to carefully read the manufacturer's instructions before proceeding.

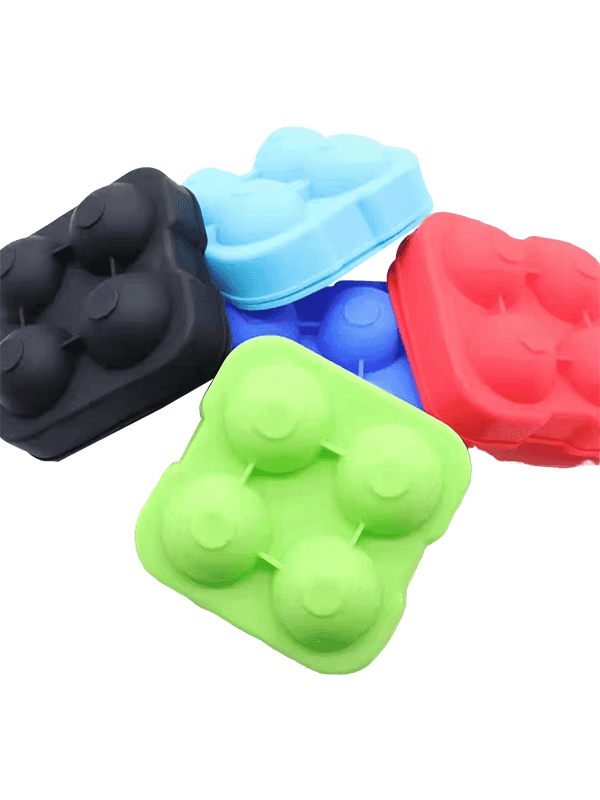

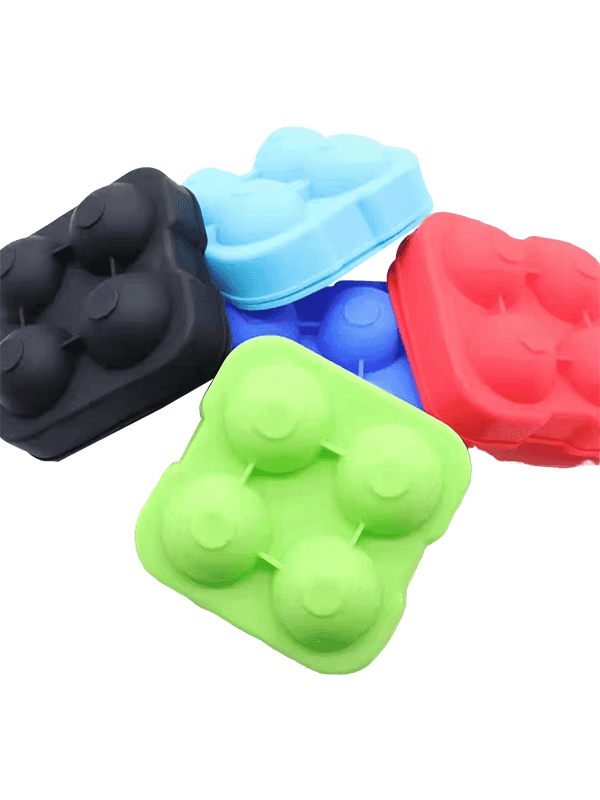

When using silicone, it is always wise to grease the inside of your mold. This will help ensure that your finished product has a smooth and easy release. Alternatively, you can use a non-stick spray to achieve the same result. This is particularly important when working with food-grade silicone, as it will be used to form delicate preparations such as cakes, cupcakes, or ice pops.

Before you can actually begin casting, it is important to decide whether you want to create a one-piece or two-piece silicone mold. A one-piece mold is similar to an ice cube tray, and it will work best with designs that have flat sides and no deep undercuts. This type of mold is easy to create and will be quick to set.

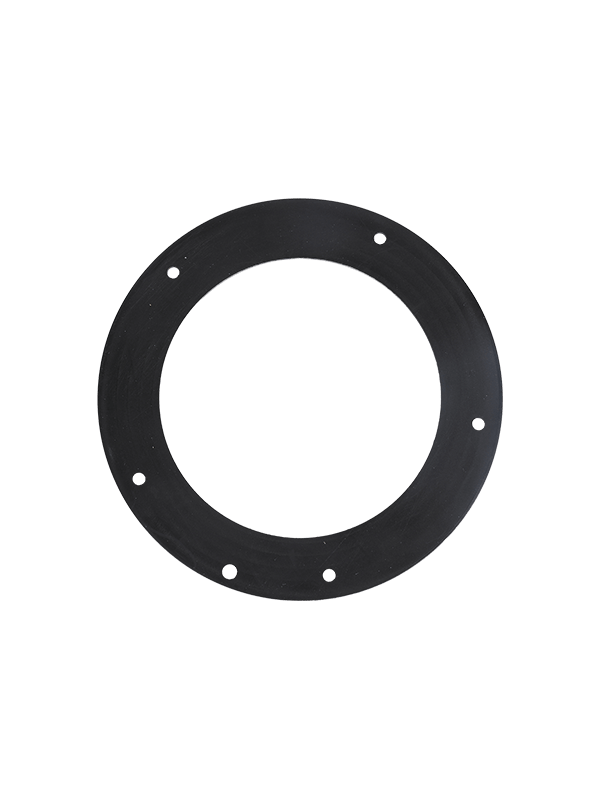

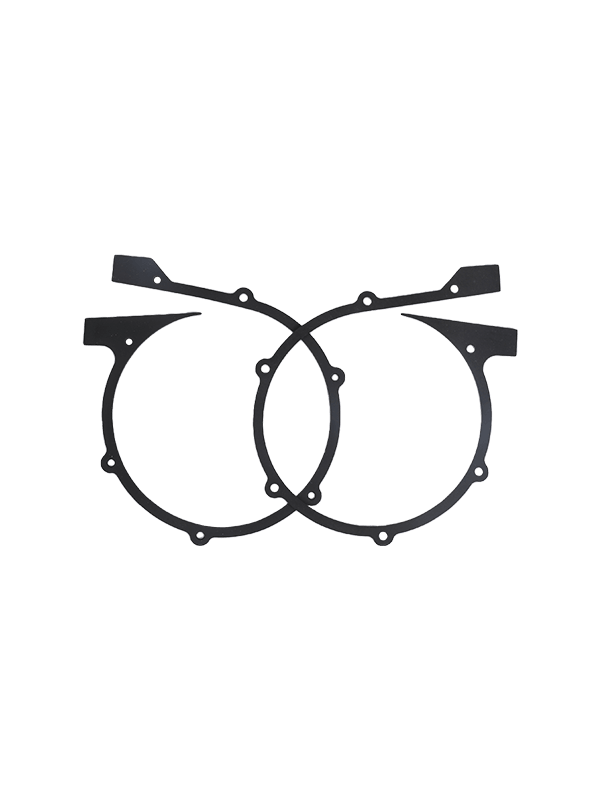

On the other hand, a two-piece silicone mold is better suited for 3D printed masters that have a complicated shape with lots of undercuts and edges. This type of silicone mold will require more time to build, but it can produce a much more precise part with fewer errors and no cracks or tears.

When working with a two-piece silicone mold, it is recommended that you heat the empty molds before use. This will prevent them from sticking to each other when you remove them. Ideally, you should clean your silicone molds with soap and water before and after each use. This will not only keep them looking new, but it will also help to prevent micro-scratches and deposits of fabric particles from building up over time. After cleaning your molds, it is also important to let them dry completely before using them again. For more information about silicone mold making, download our Silicone Molding for Product Design white paper today.