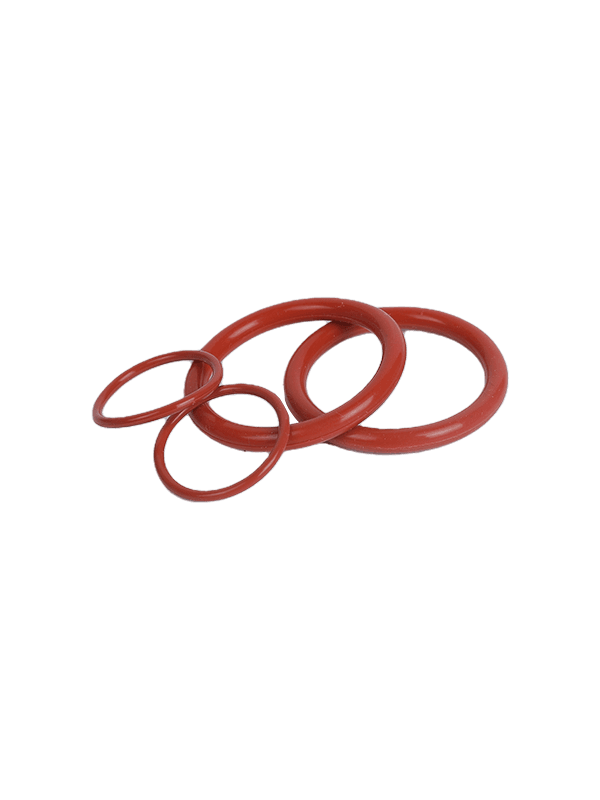

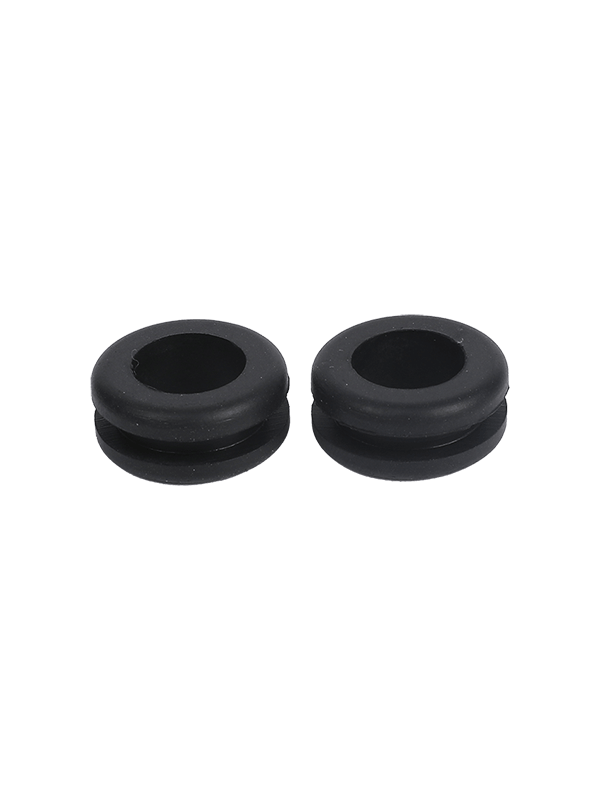

Several factors can cause silicone seal rings to leak. Understanding these factors can help in troubleshooting and preventing leaks. Here are some common causes:

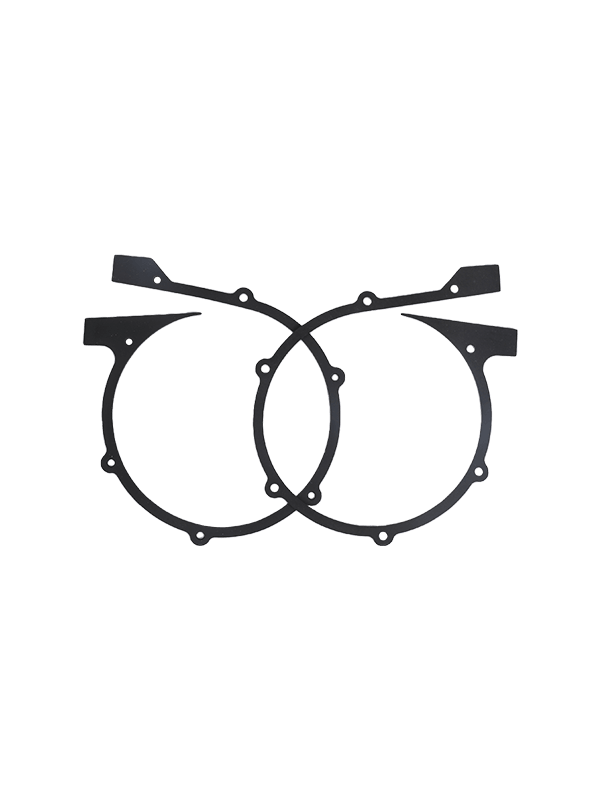

Improper Installation: If the silicone seal ring is not installed correctly, it may not create a proper seal. This could happen if the seal is not placed in the groove correctly or if it is twisted or damaged during installation.

Damage or Wear: Over time,

silicone seal rings can wear out or become damaged due to repeated use, exposure to chemicals, high temperatures, or mechanical stress. Any cracks, tears, or deformities in the seal can compromise its ability to maintain a tight seal.

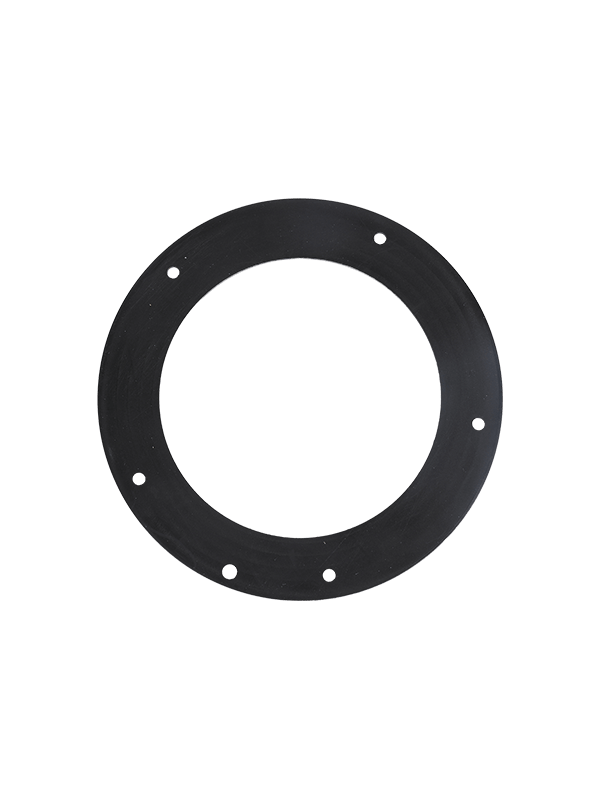

Inadequate Compression: Silicone seal rings rely on compression to create a tight seal. If the seal is not compressed sufficiently, it may not make proper contact with the mating surfaces, allowing leaks to occur.

Surface Roughness or Irregularities: Uneven or rough mating surfaces can prevent the silicone seal ring from achieving a uniform seal. Surface imperfections can create gaps or channels through which fluids or gases can leak.

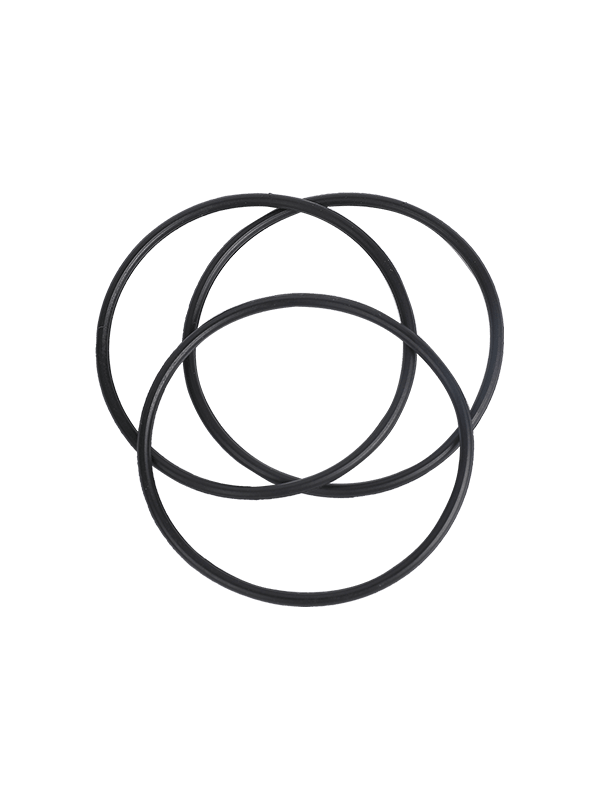

Chemical Compatibility Issues: Some chemicals or substances may react with silicone seal rings, causing degradation or swelling that compromises the integrity of the seal. It's essential to ensure that the seal material is compatible with the substances it will come into contact with.

High Temperatures: Excessive heat can cause silicone seal rings to lose their elasticity and become less effective at maintaining a seal. In extreme cases, the seal material may degrade or melt, leading to leaks.

Excessive Pressure: Silicone seal rings are designed to withstand certain pressure levels. Exceeding the recommended pressure limits can cause the seal to deform, extrude, or fail, resulting in leaks.

Improper Sizing: Using a seal ring that is too small or too large for the application can prevent it from creating an effective seal. It's important to select a seal ring with the correct dimensions and specifications for the intended use.

Aging and Degradation: Over time, silicone seal rings may degrade due to exposure to environmental factors such as UV radiation, ozone, and moisture. This can lead to deterioration of the seal material and an increased risk of leaks.

By identifying and addressing these potential causes, it's possible to minimize the risk of leaks and ensure that silicone seal rings maintain effective seals over time. Regular inspection, maintenance, and replacement of seals as needed can help prevent leaks and ensure the integrity of sealed systems and components.