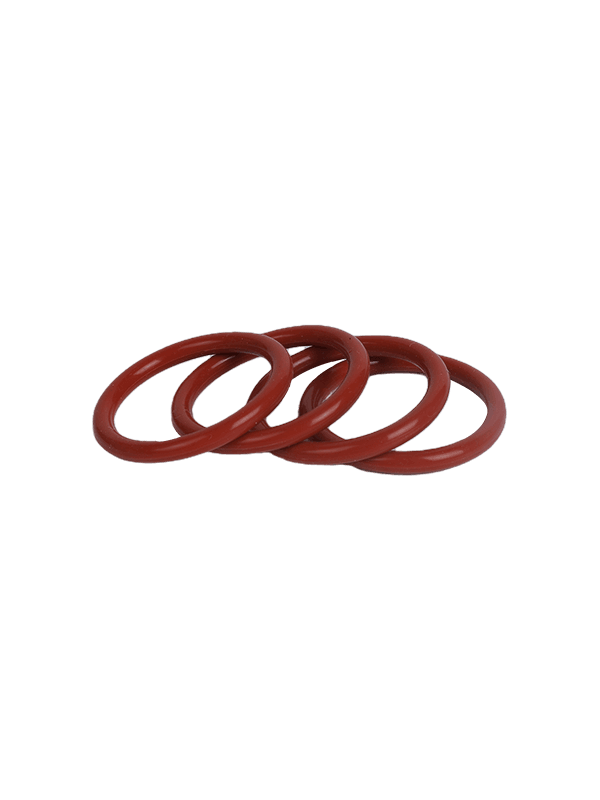

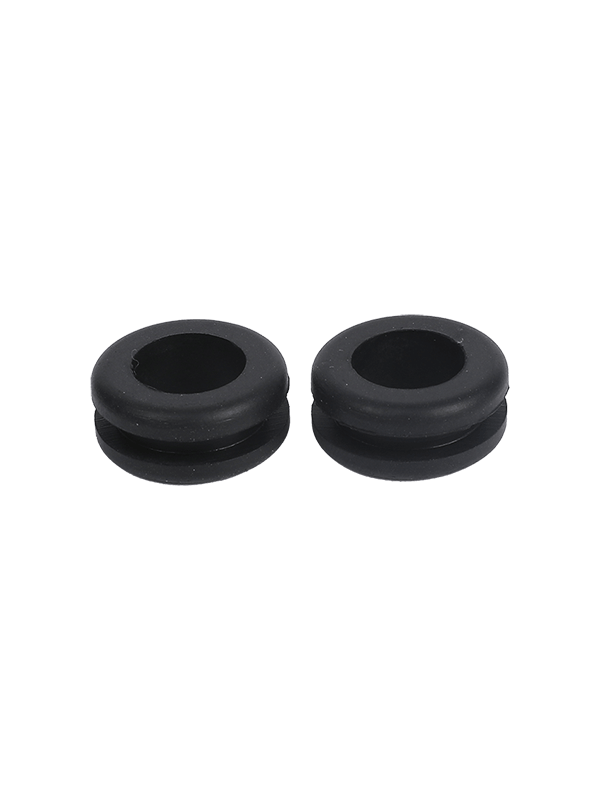

When purchasing

silicone sealing rings, there are several important factors to consider to ensure you get the right product for your specific needs. Here's what you should pay attention to:

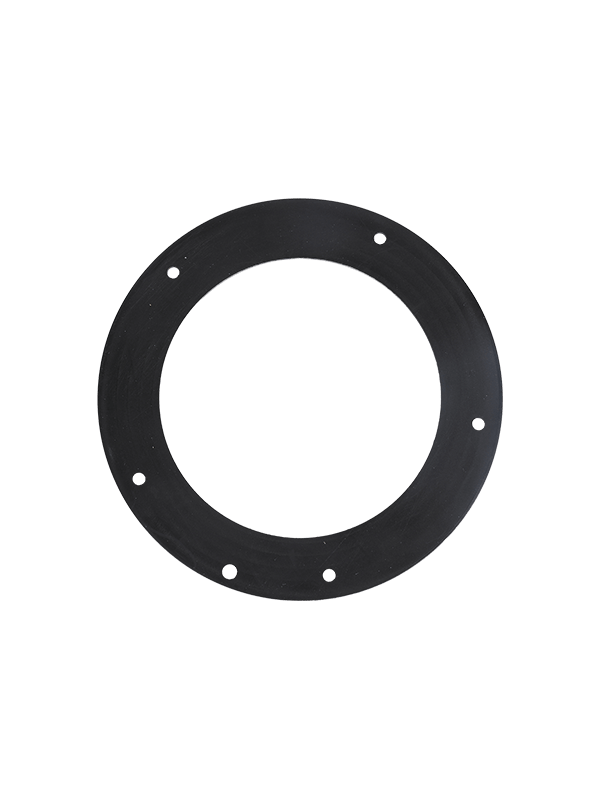

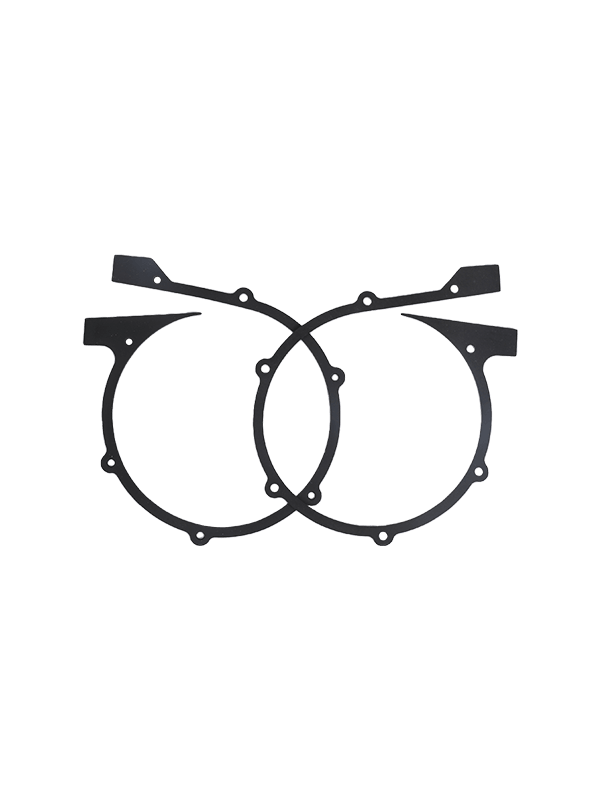

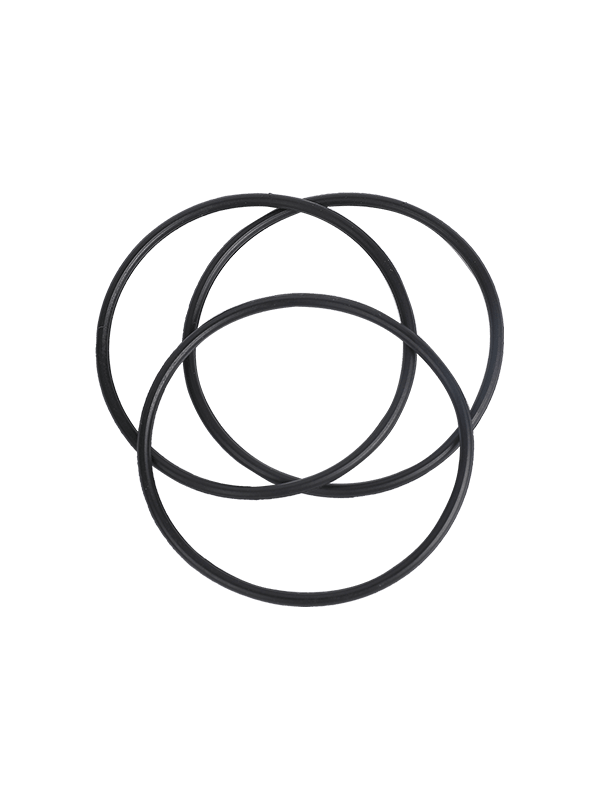

Size and Dimensions: Ensure that you select sealing rings that are the correct size and dimensions for your application. Measure the diameter, thickness, and shape of the sealing surface to ensure a proper fit.

Temperature Resistance: Consider the temperature range that the silicone sealing ring needs to withstand. Choose a sealing ring that offers sufficient temperature resistance for your specific application, whether it involves high heat, cold temperatures, or fluctuations in temperature.

Material Quality: Pay attention to the quality of the silicone material used in the sealing ring. Opt for high-quality silicone that is durable, flexible, and resistant to tearing, cracking, and degradation over time.

FDA Approval (if applicable): If the sealing ring will be used in food-related applications or environments where food contact may occur, ensure that it is made from FDA-approved silicone that is safe for use with food.

Chemical Compatibility: Consider the chemicals or substances that the sealing ring may come into contact with in your application. Choose a silicone material that is compatible with the chemicals it will be exposed to, and verify its resistance to corrosion and degradation.

Pressure Rating: If the sealing ring will be used in applications involving pressure, ensure that it is rated to handle the pressure levels required without leaking or failing.

Manufacturer Reputation: Purchase silicone sealing rings from reputable manufacturers known for producing high-quality, reliable sealing products. Read reviews and seek recommendations from trusted sources to ensure product quality and customer satisfaction.

Price and Value: Compare prices from different suppliers to ensure you are getting a competitive price for the quality and features offered. Consider the overall value of the sealing rings in terms of performance, durability, and reliability.

Compatibility: Ensure that the silicone sealing ring is compatible with the equipment, containers, or machinery it will be used with. Consider factors such as groove dimensions, mating surfaces, and installation requirements to ensure compatibility and proper sealing.

By paying attention to these factors, you can select silicone sealing rings that meet your specific requirements and provide effective sealing solutions for your applications.